MaterialsDiamond sp3 layering

DIAMOND CRYSTAL / FULLERENE DEPOSITSWe have strong indications that our systems deposit fullerene structures on conductive materials like copper, gold, silver and alloys. This needs to be confirmed by further testing by competent scientific institutes.

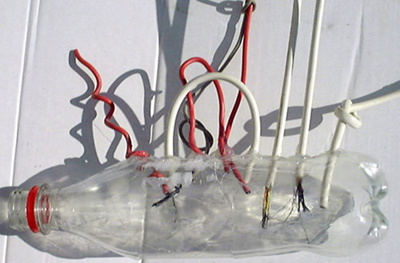

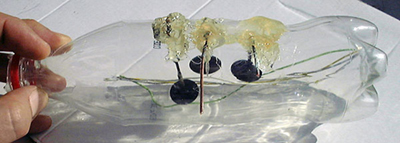

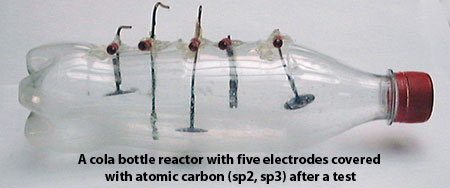

Tests performed with the Electronic Diamond Tester  Several objects were introduced into static Keshe reactors. The image above shows some of the tested objects, which are: Copper and Nordic gold eurocent coins, a silver ring, a gold ring with a diamond, electric copper wires, a telephone wire, nut and bolt, a washer, an Egyptian cartouche of pure silver with gold-plated symbols, knotted copper strands, copper foils, a lattice, a rusted piece of metal. Other objects were treated similarly but the results are not disclosed yet. RESULTS OF TESTSAll objects are coated with diamond or fullerene layer(s)

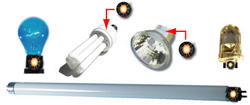

NEW MATERIALS AND SURFACE TREATMENTSThis new atomic deposition process can be used for all kinds of industrial processes, such as the protection of silver objects against oxidation, anti-humidity/waterproof protection layers on the electronic parts of mobile phones, computers, cameras, televisions and satellites, the production of new types of integrated circuits, new types of electronic parts like capacitors, LED's, switches, etc., the inner and outer protection of metal tubes, and the surfaces of airplane wings, engine and gear parts, etc.

New method of producing Graphene

The basic approach shown in the cola bottle reactor can easily be applied for large-scale industrial production. For example, we can design specific reactors to produce only sp3, thus to manufacture industrial diamond, transparent diamond and glassy carbon for various industrial applications. The presence of pure transparent diamond crystals on special electrodes was confirmed by experts in the Diamond Bourse of Antwerp. A project to produce transparent diamonds in dynamic reactors will be started. In addition it is easy to produce boron nitrides, in mono-layers (a-BN). We can also treat various materials which are covered by insulation, such as telephone wires. Already during tests in mid 2006 other properties were observed, such as porous C-structures which can be used for environmental cleaning. This is part of our IP. In April 2007 ESRF claimed the same discovery. A similar system can be used for cleaning up CO2, NOx and SO2 from automotive, home and industrial exhaust gases. Adapted versions of these reactors can be used in water treatment systems to extract elements like Cadmium and Chromium. Also Trichloroethylene can be extracted from contaminated water in a simple way by using the electromagnetic fields in the plasma. TCE is widely found in drinking water, and California has some of the nation's worst contamination. (Article LA Times, 27 July 2006)

Please keep in mind that we consider the production of graphene as only one of the by-products of our plasma technology.

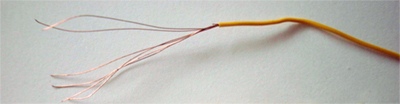

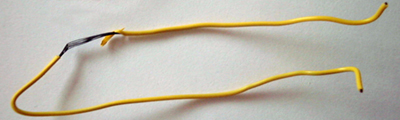

Atomic Carbon coated cables and wires

We have carried out several materials tests in our static reactors. One is the treatment of cables and wires that have copper strands inside their insulation coating. All copper wires and strands were still in their insulation sheath while being processed. Different types of cables and wires were introduced into or connected to plasma reactors. Some reactors were filled with some Kt Liquid, others only with pure plasma (a Kt Liquid vapor). No additional external energy sources - such as EUV from arcs, magnetic fields from solid magnets, electrical current, etc. - were used.

TWO KINDS OF TREATMENT

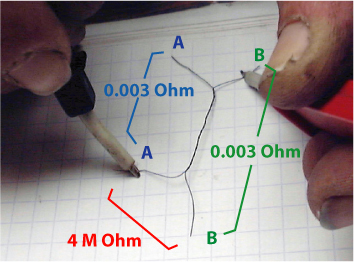

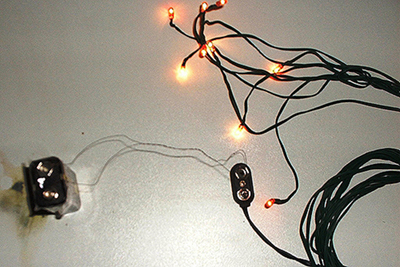

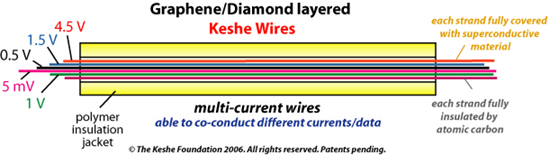

NEW INSULATING AND CONDUCTIVE PROPERTIESAlthough the strands are in direct contact, they are fully insulated from each other by the atomic carbon layers. This is proven in tests - at room temperature - with multi-meters and physical tests with batteries (9V) and lighting, where current was conducted through wires that were directly twisted round each other.

This means that a new proprietary type of wire has been developed, which can co-conduct several strengths of current at the same time through their different strands, and this will mean a revolution for all kinds of electric and electronic design.  This approach can also be used for the design of transistors and integrated circuits. For example, surfaces with only a few atomic carbon layers – such as sp2 (Graphene) with ballistic conductive properties - can be mounted directly on each other while remaining insulated from each other. With techniques like etching special circuits can be made. Mr Keshe: "It is clear that we have found a number of new principles of atomic interactions and reaction on the atomic level, which were unknown till now. We developed methods of generating new processes in our reactors, and the coating of wires which are still in their insulation sheath is just one of the industrial applications we see. "When you are working at the atomic and nano level you are thinking in other sizes. Let’s say if the carbon atoms were the size of ping-pong balls then the insulation material - which we normally think of as being very close to the copper strands - could have gaps like tens of meters wide from the copper strands themselves, so the carbon atoms can travel easily through and be deposited on the free copper atoms which attract them. "Our method is that we mount full telephone cables in the wall of our reactors, leaving the rest of the cable outside the reactor, and the cables act like exhaust pipes to transport the atomic carbon while depositing them on the copper. This is a process at atomic level, not a chemical process, since the insulation of the wires is still intact. "We can apply this amazing wire treatment on the atomic and nano level immediately on an industrial scale. The process is quite simple. This new achievement confirms our previous findings that Carbon sp2 and sp3 can be deposited on various substrates and objects at room temperature and normal atmospheric pressure, without complicated systems like the traditional arcs treatment. We can provide industry with all kinds of nano-materials at very competitive prices." Of course the methods and applications are under patent pending, since they will change and simplify a large number of industrial processes, and this not only on the nano scale. Furthermore the original approach developed by Mr Keshe makes it possible to create self-sustaining energy systems that will lead to new kinds of electric generator. New materials

LIGHTING, APPLIANCES AND TOOLS THAT NEED NO ELECTRIC WIRING

Subcategories |